What you'll learn

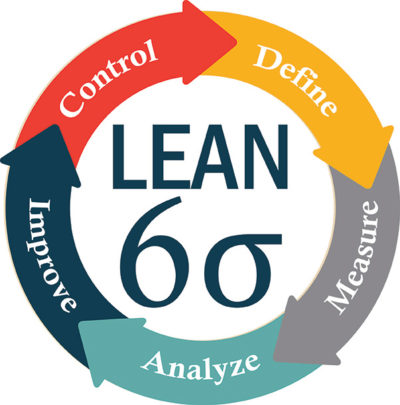

- To apply the Six Sigma methodology in your work or research, using the DMAIC process improvement cycle for identifying problems and quantitatively assess the impact of process changes

- To contribute actively in Six Sigma improvement projects by applying the necessary statistical analyses, interpreting the results, and driving change

- To perform process capacity analysis to evaluate process performance in terms of resource utilization and set up times in order to optimize throughput and minimize inventory

- To initiate Lean manufacturing transformation and analyze the new process flows to quantitatively assess productivity improvements

- To coach and motivate your colleagues to improve quality and productivity with Six Sigma and Lean

- Opportunities for advancement and leadership in quality management and continuous improvement initiatives

- Implementing Lean tools such as 5S, Pareto Charts, Flow Charts, Minitab and Kaizen for continuous improvement

Ranked as the top Lean Six Sigma certification course 🏆

Aligned with IAQMC, our program integrates Lean and DMAIC methodologies to impart essential skills.

Participants gain hands-on experience through over 16 projects, ensuring comprehensive Six Sigma certification.

Choose from flexible learning options including classroom and live online sessions, all-inclusive with exam preparation.

32 Hours of Instructor-Led Sessions

Gain comprehensive knowledge through live sessions led by experienced instructors.

9 Hours of Live Interactive Doubt Solving Sessions

Engage in interactive sessions to resolve doubts in real-time.

5 Hours of Live Master Sessions by Industry Experts

Learn from industry leaders through exclusive master sessions.

122 Hours of Self Paced Learning

Access learning materials at your own pace to deepen your understanding.

Job-Ready Portfolio of 3 Quality Management Projects

Showcase your skills with practical projects designed to simulate real-world scenarios.

29 Auto-Graded Assessments

Measure your progress with automated assessments and quizzes.

6+ Industry Case Studies

Analyze real industry cases to apply theoretical knowledge in practical contexts.

42 Guided Hands-On Exercises

Enhance your skills through guided exercises focusing on practical application.

3+ Assignments and Mini Projects

Complete assignments and mini projects to reinforce learning and skill development.

3 Mock Interview and 1 Hackathon

Prepare for real-world scenarios with a mock interview and participate in a challenging hackathon.

Get 1-Year Silver Membership of IAQMC

Access exclusive benefits and resources with IAQMC's Silver membership.

Get a guaranteed Internship in top MNC's

Secure an internship opportunity with top companies through IAQMC's partnership with leading organizations.

Get 3 in 1 Placement Support

Receive comprehensive placement support including placement drives, job portal access, and personalized job consulting.

3 Hours of Mentorship by Industry Experts

Receive mentorship from industry experts to guide your career development.

Meet Our Trainers

Our trainers are industry veterans with over 18 years of experience.

Handpicked by our partners and recognized for their remarkable contributions.

They have delivered more than 160 keynote sessions and over 350 lectures, affiliated with IAQMC.

Exclusive Silver Membership Perks

- Access to e-learning resources, including recorded videos, games, projects, and case studies.

- 5+ masterclass sessions for skill enhancement.

- Guaranteed internships with IAQMC or partners.

- Regular job opportunities post-certification.

- Interview preparation support.

- Exclusive access to additional modules like Soft Skill Development and Resume Writing.

Career Advancements with Lean Six Sigma Certification

- Qualify for highly sought-after jobs with our renowned Lean Six Sigma Certification.

- Address the shortage of talented professionals in high-paying Lean Six Sigma roles.

- Unlock international job opportunities requiring Lean Six Sigma specialization.

- Boost your CV and LinkedIn profile.

- Stand out in job interviews with a highly valued skill set gained through our certification.

- Enhance startup quality and performance for superior products and services.

Learning Advantages

- Develop data-driven problem-solving skills and statistical inference-based decision-making abilities.

- Learn to explore, analyze, and solve management issues using over 20 management tools.

- Earn 34 PDUs (Professional Development Units).

- Sharpen business acumen and dedication to process improvement.

- Extract valuable insights from data with various statistical tools.

- Acquire project management and leadership skills.

- Implement customer-centric actions at every stage of your projects.

- Master the science of developing high-quality products and services.

- Apply a domain-independent methodology to look beyond your current field.

Verify Your certificate

To verify the qualifications of an IAQMC Certified Professional, please complete the form below. Please note that it may take up to 48 working hours to receive a response. Providing the certificate number and service date will help streamline the verification procedure.

Curriculum

- 7 Sections

- 99 Lessons

- Lifetime

- Live Classes6

- Self-Learning2

- Define26

- 3.01.1 The Basics of Six Sigma

- 3.11.1.1 Meanings of Six Sigma

- 3.21.1.2 General History of Six Sigma & Continuous Improvement

- 3.31.1.3 Deliverables of a Lean Six Sigma Project

- 3.41.1.4 The Problem Solving Strategy Y = f(x)

- 3.51.1.5 Voice of the Customer, Business and Employee

- 3.61.1.6 Six Sigma Roles & Responsibilities

- 3.71.2 The Fundamentals of Six Sigma

- 3.81.2.1 Defining a Process

- 3.91.2.2 Critical to Quality Characteristics (CTQ’s)

- 3.101.2.3 Cost of Poor Quality (COPQ)

- 3.111.2.4 Pareto Analysis (80:20 rule)

- 3.121.2.5 Basic Six Sigma Metrics

- 3.13a. including DPU, DPMO, FTY, RTY Cycle Time

- 3.141.3 Selecting Lean Six Sigma Projects

- 3.151.3.1 Building a Business Case & Project Charter

- 3.161.3.2 Developing Project Metrics

- 3.171.3.3 Financial Evaluation & Benefits Capture

- 3.181.4 The Lean Enterprise

- 3.191.4.1 Understanding Lean

- 3.201.4.2 The History of Lean

- 3.211.4.3 Lean & Six Sigma

- 3.221.4.4 The Seven Elements of Waste

- 3.23a. Overproduction, Correction, Inventory, Motion, Overprocessing, Conveyance, Waiting.

- 3.241.4.5 5S

- 3.25a. Sort, Straighten, Shine, Standardize, Self-Discipline

- Measure20

- 4.02.1 Process Definition

- 4.12.1.1 Cause & Effect / Fishbone Diagrams

- 4.22.1.2 Process Mapping, SIPOC, Value Stream Map

- 4.32.1.3 X-Y Diagram

- 4.42.1.4 Failure Modes & Effects Analysis (FMEA)

- 4.52.2 Six Sigma Statistics

- 4.62.2.1 Basic Statistics

- 4.72.2.2 Descriptive Statistics

- 4.82.2.3 Normal Distributions & Normality

- 4.92.2.4 Graphical Analysis

- 4.102.3 Measurement System Analysis

- 4.112.3.1 Precision & Accuracy

- 4.122.3.2 Bias, Linearity & Stability

- 4.132.3.3 Gage Repeatability & Reproducibility

- 4.142.3.4 Variable & Attribute MSA

- 4.152.4 Process Capability

- 4.162.4.1 Capability Analysis

- 4.172.4.2 Concept of Stability

- 4.182.4.3 Attribute & Discrete Capability

- 4.192.4.4 Monitoring Techniques

- Analyse27

- 5.03.1 Patterns of Variation

- 5.13.1.1 Multi-Vari Analysis

- 5.23.1.2 Classes of Distributions

- 5.33.2 Inferential Statistics

- 5.43.2.1 Understanding Inference

- 5.53.2.2 Sampling Techniques & Uses

- 5.63.2.3 Central Limit Theorem

- 5.73.3 Hypothesis Testing

- 5.83.3.1 General Concepts & Goals of Hypothesis Testing

- 5.93.3.2 Significance; Practical vs. Statistical

- 5.103.3.3 Risk; Alpha & Beta

- 5.113.3.4 Types of Hypothesis Test

- 5.123.4 Hypothesis Testing with Normal Data

- 5.133.4.1 1 & 2 sample t-tests

- 5.143.4.2 1 sample variance

- 5.153.4.3 One Way ANOVA

- 5.16a. Including Tests of Equal Variance, Normality Testing and Sample Size calculation, performing tests and interpreting results.

- 5.173.5 Hypothesis Testing with Non-Normal Data

- 5.183.5.1 Mann-Whitney

- 5.193.5.2 Kruskal-Wallis

- 5.203.5.3 Mood’s Median

- 5.213.5.4 Friedman

- 5.223.5.5 1 Sample Sign

- 5.233.5.6 1 Sample Wilcoxon

- 5.243.5.7 One and Two Sample Proportion

- 5.253.5.8 Chi-Squared (Contingency Tables)

- 5.26a. Including Tests of Equal Variance, Normality Testing and Sample Size calculation, performing tests and interpreting results.

- Improve10

- 6.04.1 Simple Linear Regression

- 6.14.1.1 Correlation

- 6.24.1.2 Regression Equations

- 6.34.1.3 Residuals Analysis

- 6.44.2 Multiple Regression Analysis

- 6.54.2.1 Non- Linear Regression

- 6.64.2.2 Multiple Linear Regression

- 6.74.2.3 Confidence & Prediction Intervals

- 6.84.2.4 Residuals Analysis

- 6.94.2.5 Data Transformation, Box Cox

- Control8

Courses you might be interested in

-

23 Lessons

-

117 Lessons

-

54 Lessons